Discover readily available PDF plans for DIY queen bed frames, offering savings of hundreds – even up to $1,200 – compared to retail options!

Numerous free and paid plans exist, catering to all skill levels, from beginner-friendly designs to intricate Japanese-inspired timber framing builds.

Overview of the Project

Embarking on a queen bed frame woodworking project involves constructing a sturdy and aesthetically pleasing foundation for your mattress. PDF plans provide detailed instructions, cut lists, and diagrams to guide you through each stage, from lumber selection to final assembly.

The project typically includes building side rails, a headboard, a footboard, and internal supports or slats. Options range from simple platform beds to more elaborate designs incorporating storage or unique headboard styles. Success hinges on accurate measurements, precise cuts, and careful assembly, resulting in a custom bed frame tailored to your preferences and bedroom décor.

Benefits of Building Your Own Bed Frame

Constructing your own queen bed frame offers significant advantages, primarily substantial cost savings – potentially hundreds, even exceeding $1,200 compared to store-bought options. Beyond finances, you gain complete customization, tailoring the design, wood type, and finish to your exact tastes.

This project fosters woodworking skills and provides a unique, handcrafted piece of furniture. PDF plans simplify the process, making it accessible to beginners, while offering advanced builders opportunities for creative modifications and personalized touches.

Tools and Materials Required

Essential tools include a saw (circular or miter), drill, screwdriver, measuring tape, and safety glasses. Depending on the plan, a pocket hole jig may be beneficial. Materials typically consist of lumber – pine, oak, or maple are common – screws, wood glue, and finishing supplies like stain or paint.

PDF plans will provide a detailed cut list, specifying lumber dimensions. Budget for sandpaper, wood filler, and potentially metal accents if incorporating a modern design. Prior to starting, ensure all tools are in good working order.

Design Considerations for Queen Bed Frames

Explore platform, traditional, and Japanese-inspired designs detailed in PDF plans. Consider headboard/footboard styles and wood choices – pine, oak, or maple – for aesthetics and durability.

Platform Bed vs. Traditional Bed Frame

Queen bed frame PDF plans showcase both platform and traditional designs. Platform beds, often minimalist, eliminate the need for a box spring, utilizing slats for mattress support – a popular modern choice. Traditional frames, conversely, require a box spring and feature a more ornate structure, often with visible legs and a defined base.

PDF plans detail the construction differences; platform beds generally involve simpler assembly, while traditional frames demand more intricate joinery. Choosing between them depends on desired style, budget, and space constraints, as detailed in available woodworking guides.

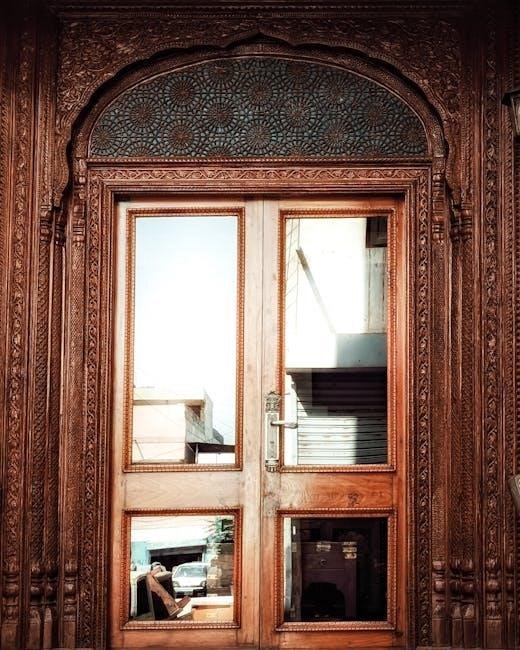

Headboard and Footboard Styles

Queen bed frame PDF plans present a diverse range of headboard and footboard styles. Options span from simple, minimalist designs to elaborate, carved panels, catering to various aesthetic preferences. Plans often include detailed diagrams for constructing classic spindle headboards, or sleek, modern upholstered versions.

Footboards can be equally varied – low-profile platforms, raised panels, or even omitted entirely for a contemporary look. PDF guides illustrate techniques for incorporating lighting into headboards, adding a functional and stylish element to your custom build.

Wood Selection: Pine, Oak, Maple, and Alternatives

Queen bed frame PDF plans frequently suggest wood choices impacting both cost and durability. Pine is a budget-friendly option, easy to work with, but less resistant to dents. Oak offers superior strength and a classic grain, increasing the project’s longevity.

Maple provides a smooth, paintable surface and is highly durable. Alternatives like poplar or birch can also be used, balancing cost and workability. Plans often detail lumber requirements based on chosen wood type.

Finding Queen Bed Frame Woodworking Plans (PDF)

Locate queen bed frame PDF plans on various websites, ranging from free options to premium, detailed guides, readily available for download today!

Free vs. Paid Plans: A Comparison

Free queen bed frame PDF plans offer a budget-friendly starting point, often providing basic designs suitable for beginners, though detail can be limited.

Conversely, paid plans – priced around $11.00 – typically deliver comprehensive instructions, detailed diagrams, and cut lists, ensuring a smoother build process.

Premium plans frequently include advanced techniques, material optimization, and even variations for different wood types, justifying the investment for experienced woodworkers.

Ultimately, the choice depends on skill level, desired complexity, and the value placed on detailed guidance versus cost savings.

Popular Websites Offering Plans (2023-2024)

Numerous online resources provide queen bed frame PDF plans, catering to diverse woodworking skill levels. Several websites feature easy-to-follow DIY bed frame projects.

Specifically, platforms offer printable plans, including options for platform beds, headboards, and even Japanese-inspired designs with wedge-lock systems.

Many sites provide both free and paid options, with premium plans often boasting detailed diagrams and step-by-step assembly instructions for a successful build.

Exploring these resources unlocks a world of possibilities for crafting a custom bed frame tailored to individual preferences and bedroom aesthetics.

Evaluating Plan Quality: What to Look For

When selecting queen bed frame woodworking plans (PDF), prioritize clarity and completeness. Essential features include detailed cut lists, specifying lumber dimensions and quantities accurately.

Look for plans with comprehensive diagrams illustrating assembly steps and screw placement. High-quality plans will also offer material lists and tool requirements.

Consider the skill level indicated; beginner plans should have simpler joinery, while advanced plans may involve more complex techniques. Ensure the plans are easy to understand.

Finally, check for user reviews or feedback to gauge the plan’s accuracy and buildability before committing to the project.

Step-by-Step Construction Guide (Based on Common Plans)

Begin by precisely cutting lumber according to your chosen PDF plan’s dimensions. Then, assemble side rails, followed by headboard and footboard construction.

Finally, install bed supports and slats for a sturdy, comfortable queen bed frame.

Cutting the Lumber According to the Plan

Accurate lumber cutting is paramount; meticulously follow the cut list within your chosen PDF plan. Double-check all measurements before each cut to minimize errors and material waste.

Utilize appropriate saws – circular, miter, or hand saws – ensuring clean, straight cuts. Pay close attention to angle specifications for headboard and footboard pieces. Label each cut piece clearly, referencing the plan’s diagrams for easy assembly. Prioritize safety by wearing protective eyewear and following safe sawing practices.

Remember that precise cuts contribute significantly to the overall structural integrity and aesthetic appeal of your finished queen bed frame.

Assembling the Side Rails

Begin side rail assembly by connecting the pre-cut lumber pieces, typically using screws or pocket hole joinery as detailed in your PDF plan. Ensure squareness during this stage – a framing square is invaluable.

Reinforce corners with additional blocks or brackets for added stability, especially crucial for supporting mattress weight. Pre-drill holes to prevent wood splitting, particularly with hardwoods. Confirm the assembled rails are level and of equal length before proceeding.

Properly assembled side rails form the foundational support for the entire bed frame structure.

Constructing the Headboard and Footboard

Headboard and footboard construction varies greatly depending on your chosen PDF plan’s style – from simple, minimalist designs to elaborate, decorative pieces. Begin by assembling the frame using screws and wood glue, ensuring square corners.

Attach any decorative panels or spindles, following the plan’s detailed diagrams. Consider incorporating curves or unique shapes for a custom look. Sand all surfaces smooth before finishing.

Securely attach the completed headboard and footboard to the side rail assembly, creating the bed’s defining shape.

Building the Bed Supports and Slats

Bed supports, crucial for mattress stability, are typically constructed from 2×4 lumber, secured to the inside of the frame with screws and glue. Ensure these supports are evenly spaced and level for optimal weight distribution.

Slats, providing the mattress foundation, are placed across the supports. PDF plans often specify slat spacing based on mattress type; closer spacing is needed for memory foam.

Secure slats with screws or specialized slat holders, preventing shifting and ensuring a quiet, comfortable sleep.

Advanced Techniques & Customizations

Elevate your DIY bed with under-bed storage, integrated lighting in the headboard, or refined finishes like staining, painting, and protective sealing.

Adding Under-Bed Storage

Maximize bedroom space by incorporating under-bed storage into your queen bed frame design. PDF plans often showcase various approaches, from simple open cubbies ideal for storing bedding to more elaborate drawer systems requiring additional woodworking skills.

Consider the height of your bed frame and the available clearance when planning storage solutions; Utilize pull-out drawers on smooth-gliding runners for easy access, or build fixed compartments with lift-up lids. Remember to account for weight distribution and structural support to ensure the bed remains stable and safe.

Incorporating Lighting into the Headboard

Elevate your bedroom’s ambiance by integrating lighting directly into your queen bed frame’s headboard. PDF plans may suggest pre-designed features or inspire custom solutions. Consider subtle LED strip lighting along the headboard’s perimeter for a soft glow, or recessed spotlights for focused reading.

Plan for electrical wiring and outlets during construction, prioritizing safety. Ensure all wiring is concealed and meets electrical code requirements. Think about adding dimmer switches for adjustable brightness and creating a relaxing atmosphere.

Finishing Techniques: Staining, Painting, and Sealing

PDF woodworking plans often detail finishing options to protect and beautify your queen bed frame. Staining enhances wood grain, while painting allows for customized color schemes. Proper surface preparation – sanding – is crucial for adhesion.

Apply multiple thin coats for a durable finish. Sealing with polyurethane or varnish provides protection against scratches and moisture. Consider the desired aesthetic and longevity when selecting your finishing technique, ensuring a beautiful, lasting result.

Safety Precautions for Woodworking

Prioritize safety when building from PDF plans! Wear protective gear, ensure proper ventilation, and master safe power tool operation to prevent injuries.

Using Power Tools Safely

When utilizing power tools based on your queen bed frame PDF plans, always read and understand the manufacturer’s manual before operation. Ensure all safety guards are in place and functioning correctly. Wear safety glasses or a face shield to protect your eyes from flying debris.

Use hearing protection when operating loud tools like saws or routers. Maintain a firm grip and stable stance while working. Never force a tool; let it do the work. Disconnect power tools when changing blades or making adjustments. Be mindful of the cord’s location to avoid tripping or accidental cuts.

Proper Ventilation and Dust Control

Woodworking, especially when following queen bed frame PDF plans, generates significant dust. Adequate ventilation is crucial for a healthy workspace. Open windows and doors, or use an exhaust fan to remove airborne particles. Consider a dust collection system connected to your power tools.

Wear a dust mask or respirator to prevent inhaling fine particles. Regularly clean your workspace to minimize dust accumulation. Avoid sweeping, which stirs up dust; instead, use a vacuum with a HEPA filter. Protect your lungs and maintain a clean, safe environment.

Wearing Protective Gear

When building a queen bed frame from PDF plans, safety is paramount. Always wear safety glasses to protect your eyes from flying debris. Hearing protection, like earplugs or earmuffs, is essential when using loud power tools. Gloves can improve grip and shield hands from splinters.

A dust mask or respirator prevents inhalation of wood dust. Sturdy footwear protects your feet. Appropriate clothing avoids loose fits that could get caught in machinery. Prioritize your well-being with comprehensive protective gear.

Cost Analysis: Building vs. Buying

Building a queen bed frame using PDF plans can save significantly – potentially hundreds – compared to purchasing a pre-made bed, factoring in materials and labor.

Material Costs Breakdown

Estimating material expenses for a DIY queen bed frame, guided by PDF plans, requires careful consideration. Lumber costs vary significantly based on wood type – pine being the most affordable, while oak or maple increase the price.

Expect to spend between $150-$400 on lumber alone, depending on your choice. Additional expenses include screws, wood glue, sandpaper, and finishing supplies like stain or paint, adding another $50-$100.

Hardware like bed slats or support systems can contribute $30-$70 to the total material cost.

Labor Cost (Your Time)

Calculating the “labor cost” involves valuing your time spent building from PDF plans. A simple queen bed frame might take a dedicated weekend – roughly 16-24 hours – for a reasonably skilled woodworker.

More complex designs, especially those with headboards or intricate details, could easily extend to 30+ hours.

Assigning an hourly rate to your time (even a modest $20-$30/hour) reveals a significant investment. While not an out-of-pocket expense, acknowledging this cost is crucial for a realistic cost analysis.

Potential Savings

Building a queen bed frame from PDF plans offers substantial savings. Comparable beds retail between $800 and $1,200, depending on wood type and finish.

Material costs typically range from $200 to $500, depending on wood selection – pine being the most affordable, oak and maple more expensive.

Factoring in your labor, savings can still be $300-$700, or even more, compared to purchasing a pre-made bed, making DIY a financially attractive option.

Troubleshooting Common Issues

Address wood splitting with proper pre-drilling; ensure square, level construction during assembly; and eliminate squeaks by tightening all fasteners regularly.

Dealing with Wood Splitting

Wood splitting during screw or nail insertion is a common issue, especially with drier lumber. Prevent this by always pre-drilling pilot holes, ensuring they are slightly smaller than the fastener’s shank.

Consider using screws designed for hardwoods, even with softer woods like pine, as they often have self-tapping features. If splitting occurs, apply wood glue to the crack and clamp it until dry, reinforcing the joint.

Avoid over-tightening fasteners, as this exacerbates the problem. Carefully select lumber, avoiding pieces with existing cracks or knots near the joinery points.

Ensuring Square and Level Construction

Maintaining squareness and levelness is crucial for a stable and aesthetically pleasing bed frame. Frequently check angles with a speed square during assembly, adjusting as needed. Utilize clamps to hold pieces firmly in place while gluing and fastening.

A level surface is essential for initial construction; use shims if your floor is uneven. Regularly check for square using the 3-4-5 triangle method – ensuring accurate measurements along diagonals.

Don’t rush the process; precise alignment at each stage prevents cumulative errors and ensures a robust final product.

Addressing Squeaking Bed Frames

Squeaking often arises from wood rubbing against wood or loose joints. Inspect all connections – side rails, headboard, footboard, and supports – tightening screws and bolts. Apply beeswax or furniture lubricant to joints where wood contacts wood, reducing friction.

Check the bed slats, ensuring they are securely fastened and not rubbing against the frame. Consider adding felt pads to contact points. If the floor is uneven, leveling the bed can eliminate squeaks.

Persistent squeaks may indicate structural issues requiring further investigation and repair.

Resources for Additional Help

Explore online woodworking forums and YouTube tutorials for guidance. Consider local woodworking classes to enhance skills and receive personalized instruction.

Online Woodworking Forums

Engage with experienced woodworkers on dedicated online forums to ask questions, share progress, and receive valuable feedback regarding your queen bed frame project.

These communities often host detailed discussions about specific plans, troubleshooting common issues, and alternative techniques. Members frequently share their own modifications and customizations, offering inspiration beyond the original PDF instructions.

Look for forums specializing in bed building or general woodworking, ensuring a focused and knowledgeable audience to support your build. Don’t hesitate to post pictures of your work for constructive criticism!

YouTube Tutorials

Supplement your PDF plans with visual guidance from YouTube tutorials. Many woodworkers create step-by-step videos demonstrating bed frame construction, offering a clearer understanding of complex techniques.

Search specifically for tutorials related to the plan you’ve chosen, or for general queen bed frame builds to grasp fundamental concepts. Visual learners will benefit greatly from seeing the assembly process in action.

Pay attention to tool usage and safety demonstrations, ensuring a successful and secure build. Remember to cross-reference video instructions with your PDF plan for accuracy!

Local Woodworking Classes

Consider enrolling in local woodworking classes to enhance your skills before tackling a queen bed frame project. Hands-on instruction from experienced instructors can provide invaluable guidance and address specific challenges.

These classes often cover essential techniques like joinery, wood finishing, and safe tool operation, directly applicable to bed frame construction. Furthermore, you’ll gain access to a workshop equipped with specialized tools.

Networking with fellow woodworkers offers support and inspiration, while personalized feedback ensures a high-quality finished product. Combine class learning with your PDF plans!

Understanding PDF Plan Symbols and Diagrams

Decipher woodworking symbols, assembly diagrams, and cut lists within PDF plans for successful bed frame construction. Detailed drawings ensure accurate material usage and assembly.

Decoding Common Woodworking Symbols

PDF woodworking plans utilize standardized symbols to convey crucial information efficiently. Arrows indicate grain direction, vital for wood strength and appearance. Circle and cross symbols denote screw hole locations and types – countersunk versus standard. Lines with numbers represent dimensions, while dashed lines signify hidden features.

Understanding these symbols is paramount for accurate lumber cutting and assembly. Pay close attention to symbols indicating joinery methods, like mortise and tenon or pocket holes. Familiarizing yourself with these visual cues ensures a smooth and error-free building process, translating the PDF plan into a beautiful, sturdy queen bed frame.

Interpreting Assembly Diagrams

Queen bed frame PDF plans feature assembly diagrams illustrating the construction sequence. Exploded views showcase how components fit together, often numbered for clarity. Pay attention to the orientation of each piece – front, back, top, and bottom – to avoid errors. Arrows frequently indicate joining directions and the order of operations.

Carefully study these diagrams before cutting any lumber. Look for details like screw placement and the use of wood glue. Understanding the diagrams minimizes mistakes and ensures a structurally sound and aesthetically pleasing finished product, bringing your DIY bed frame to life.

Using Cut Lists Effectively

Queen bed frame PDF plans include detailed cut lists, specifying lumber dimensions for each component. These lists typically indicate length, width, and quantity needed, optimizing material usage and minimizing waste. Double-check measurements before cutting, accounting for the saw blade’s kerf – the width of the cut.

Organize your lumber based on the cut list, labeling each piece to avoid confusion during assembly. Efficient use of the cut list saves time, money, and frustration, ensuring accurate and consistent results throughout your DIY bed frame project.

Japanese Timber Framing Inspired Bed Frames

Explore PDF plans featuring Japanese joinery, like wedge lock systems, creating beautiful, durable, and easily disassembled queen bed frames for portability.

Adapt materials while maintaining the aesthetic and functionality of traditional Japanese timber framing techniques.

Wedge Lock System Explained

The wedge lock system, central to Japanese timber framing inspired bed frames, offers a robust and elegant joinery method. Instead of screws or nails, precisely cut wooden wedges are driven into corresponding slots, tightening the connection over time.

PDF plans detail the angles and dimensions crucial for successful wedge creation and placement. This technique allows for disassembly and relocation, a key benefit of these designs, and provides exceptional structural integrity. Proper fitting is essential for a secure, long-lasting bed frame.

Benefits of Knock-Down Designs

Queen bed frame PDF plans featuring knock-down designs offer unparalleled flexibility. These frames disassemble easily, simplifying moving and storage – a significant advantage for those who relocate frequently or have limited space.

The wedge lock system, common in these plans, facilitates this process without compromising structural stability. Furthermore, damaged components can be replaced individually, extending the bed’s lifespan and reducing overall costs. Assembly and disassembly are straightforward, even for novice woodworkers.

Material Adaptations for Japanese Style

Adapting materials for a Japanese-inspired queen bed frame, based on PDF plans, often involves selecting hardwoods like oak or maple to emulate traditional aesthetics and durability. However, pine can be a cost-effective alternative, particularly for practice builds.

Focus on clean lines and minimal ornamentation, mirroring Japanese design principles. Consider using natural finishes to highlight the wood grain, and prioritize joinery techniques like the wedge lock system for authentic construction.

Modern Bed Frame Construction Techniques

PDF plans showcase modern techniques like pocket hole joinery for strong, concealed connections, creating clean, minimalist queen bed frames with optional metal accents.

Using Pocket Hole Joinery

Pocket hole joinery is a frequently featured technique in modern queen bed frame PDF plans, prized for its strength and simplicity. This method creates robust joints by drilling angled holes and using self-tapping screws.

Many downloadable plans detail precise pocket hole placement for side rails, headboards, and footboards, ensuring a secure and aesthetically pleasing build. It’s a fantastic option for woodworkers seeking clean lines and hidden fasteners, contributing to a minimalist design.

PDF guides often include diagrams illustrating the process, making it accessible even for beginners.

Creating Clean and Minimalist Designs

Queen bed frame PDF plans increasingly emphasize clean, minimalist aesthetics, reflecting contemporary bedroom styles. These designs often prioritize simplicity, utilizing straight lines and avoiding ornate detailing.

Modern plans frequently showcase platform beds with low profiles, focusing on functionality and a streamlined appearance. Pocket hole joinery, as detailed in many PDF guides, contributes to this aesthetic by concealing fasteners.

Downloadable plans often feature material lists favoring lighter wood tones to enhance the sense of spaciousness and tranquility.

Incorporating Metal Accents

Queen bed frame woodworking plans PDF resources demonstrate a growing trend of blending wood with metal accents for a modern industrial or contemporary look. PDF guides often detail how to integrate metal legs, providing robust support and visual contrast.

Metal hardware, such as brackets and corner reinforcements, are frequently featured, enhancing both structural integrity and aesthetic appeal. Plans may suggest using steel or iron for headboard detailing.

Downloadable plans often include specifications for metal finishes, like brushed nickel or matte black, to complement the wood tones.